3D Printed Fixtures

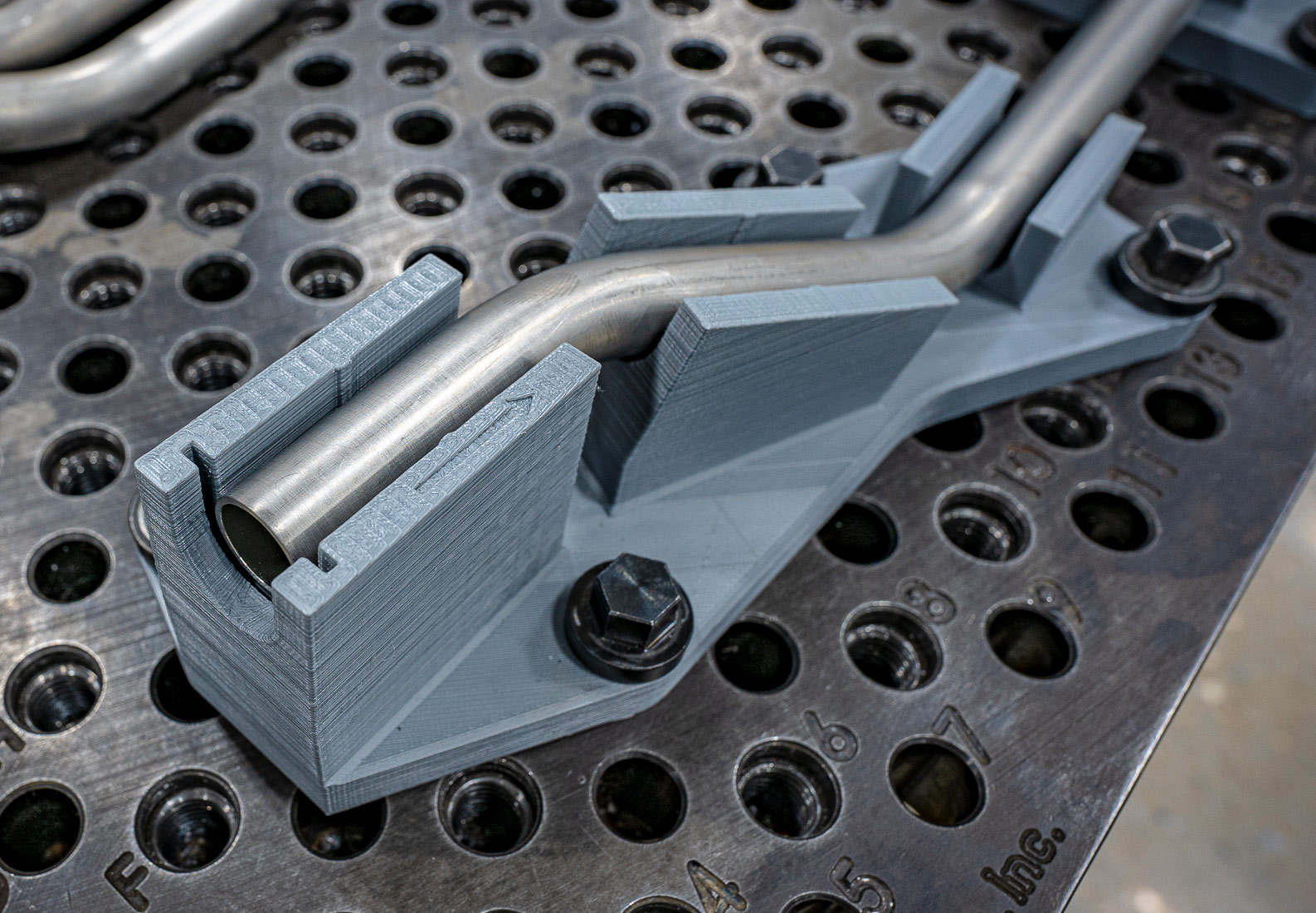

Everyday, the FX3D team is redefining the way industries measure and inspect complex parts and components. Our innovative 3D-printed fixtures provide a fast, accurate, and cost-effective solution for verifying angles, dimensions, and tolerances with precision. Unlike traditional proving fixtures, our cutting-edge approach leverages advanced 3D printing technology alongside proprietary engineering and inspection software to deliver lightweight, compact, and highly efficient Go-No-Go fixtures.

Revolutionizing Inspection with 3D-Printed Fixtures

FX3D specializes in creating 3D-printed fixtures designed to measure and verify angles and dimensions with unmatched accuracy. Our process starts with customer-furnished data, which we use to engineer Go-No-Go fixtures tailored to specific components. By utilizing state-of-the-art additive manufacturing techniques, we produce fixtures that are significantly smaller, more lightweight, and easier to store than conventional proving fixtures. This not only improves efficiency on the production floor but also reduces storage requirements and associated costs.

Certified Precision with Proprietary Scanning & Inspection Software

Ensuring accuracy and compliance is at the core of our mission. Every FX3D fixture undergoes rigorous certification using our proprietary inspection software, which validates the fixture against the solid model provided by the customer. This level of precision guarantees that the fixtures meet the highest standards, making them ideal for applications in inspection, fabrication, and welding.

Save Time | Save Space | Save Money

Precision Fixture Inspection,

Trusted by Industry Leaders

FX3D serves a broad range of industries where precision and reliability are critical.

Aerospace

Ensuring precise measurements for high-performance components used in aircraft and spacecraft manufacturing.

Automotive

Supporting efficient quality control and fabrication of vehicle parts with unmatched accuracy.

Manufacturing

Providing reliable fixtures for use in industrial fabrication and production processes.

Our commitment to excellence extends beyond just innovation.

FX3D is an ITAR-regulated and NIST-compliant company, ensuring that our processes and products meet stringent industry standards. This compliance reinforces our dedication to quality, security, and reliability, giving our clients peace of mind when integrating our services into their operations.

Experience the Future of

Fixture Inspection with FX3D

3D Innovation

FX3D is actively transforming the way companies approach precision measurement and inspection. By integrating innovative 3D printing technology with engineering excellence, we deliver next-generation solutions that enhance efficiency, accuracy, and reliability.

Compact and Lightweight

Our 3D-printed fixtures are surprisingly lightweight and take up minimal space, making storage and handling more convenient than traditional fixtures.

Fast and Accurate

With our innovative, patented 3D printing, scanning and engineering techniques, we deliver high-precision fixtures with rapid turnaround times.

Certified Quality

Each 3D fixture is checked via multiple validations against the customer’s virtual or solid model for guaranteed precision.

Regulatory Compliance

FX3D meets ITAR and NIST standards, ensuring industry-leading quality and security.