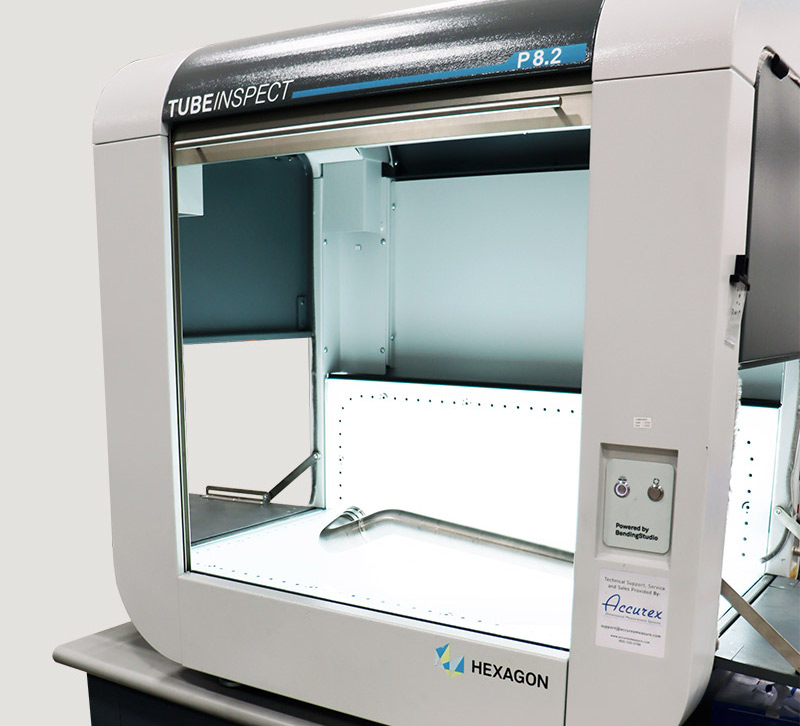

Hexagon TubeInspect

Hexagon’s TubeInspect is an optical measurement system designed specifically for bent tubes, wires, and formed parts. Using high-resolution cameras, it captures the shape and dimensions of a tube in just seconds with no physical contact required. The system compares scanned parts to CAD models or design data to confirm accuracy.

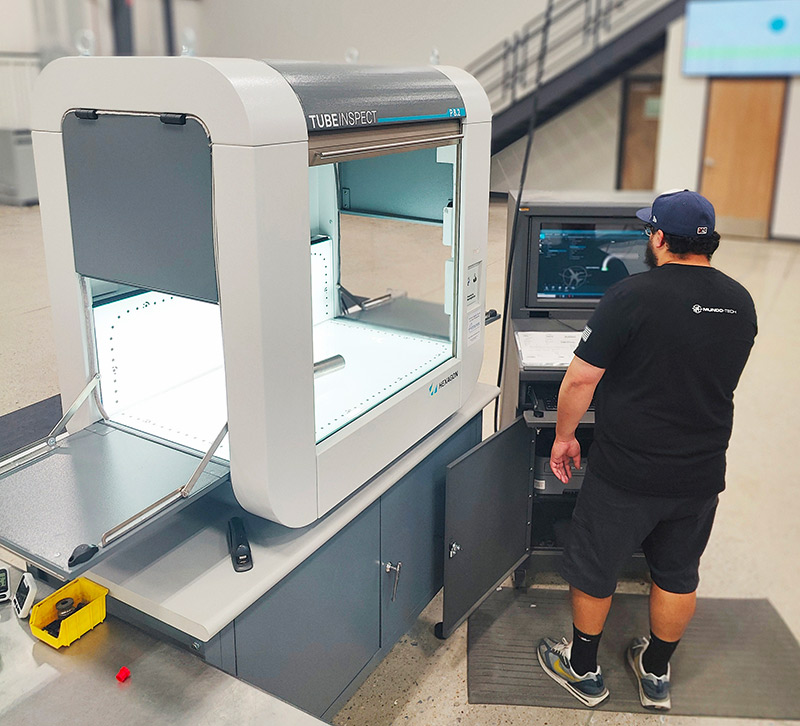

Bent tubes and formed components are a core part of the geometry we design around in our fixture development process. TubeInspect helps us check the shape of those tubes quickly and without the need for physical contact or manual tools. It gives us a fast, clear view of whether a part matches the original design, which is essential when we’re building inspection fixtures or validating a finished piece.

We use this technology to make sure the parts we’re designing around are exactly what they’re supposed to be. That allows us to deliver 3D-printed fixtures that fit perfectly and help our customers improve their own inspection and production accuracy.

Precision in manufacturing custom 3D-printed fixtures is paramount. The integration of the Hexagon TubeInspect system enhances our inspection capabilities by providing rapid, accurate measurements of complex tube geometries.

This non-contact optical system allows us to verify the dimensional accuracy of our fixtures without physical contact, preserving the integrity of delicate or intricate designs.

The quick measurement process, delivering results in as little as three seconds, enables us to maintain efficient production schedules and promptly address any deviations from design specifications. The seamless integration with BendingStudio XT software facilitates direct communication with our CNC bending machines, allowing for immediate adjustments and reducing downtime. By employing TubeInspect, FX3D ensures that our fixtures meet the highest standards of precision, thereby enhancing the quality and reliability of the products we deliver to our clients.

With this technology in place, we can verify that every part meets exact specifications, and we can document those results with confidence. Whether we are working in aerospace, defense, or commercial manufacturing, the AS1 helps us deliver fast, accurate, and traceable inspection that our customers can count on.