Innovation

Precision Modular Fixtures for Efficient, Accurate Manufacturing

FX3D is redefining the way industries measure and inspect complex parts and components. Our innovative and patented modular 3D-printed fixtures provide a fast, accurate, and cost-effective solution for verification.

FX3D Innovative Ideas

The FX3D team is committed to transforming the way companies approach precision measurement and inspection. By integrating innovative 3D printing technology with engineering excellence, we deliver next-generation solutions that enhance efficiency, accuracy, and reliability.

Magnetic Pins

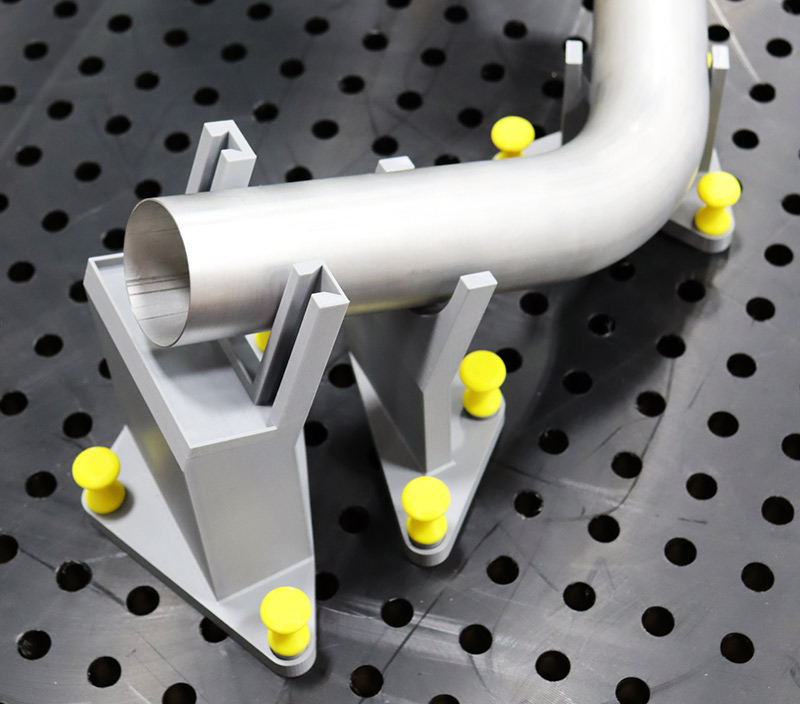

Our 3D-printed fixtures with magnetic pins offer a fast, reliable, and tool-free solution for holding parts in place during inspection. The powerful magnets create a secure grip without the need for traditional clamps or fasteners, making setup and teardown quick and easy. This innovative design reduces operator fatigue, minimizes errors, and boosts overall productivity. Ideal for rapid checks, magnetic pin fixtures streamline the verification process, ensuring that tubes and components meet precise specifications with greater efficiency.

Augmented Reality

Boost precision and consistency with our augmented reality (AR)-enabled fixtures, powered by our partner, Light Guide. These fixtures incorporate visual step-by-step instructions, helping operators follow accurate assembly and inspection processes with minimal guesswork. The AR system reduces human error by overlaying graphic representations of proper part placements and procedures, making complex assemblies easier to complete. This technology-driven solution streamlines workflows, improves accuracy, and shortens training time—ideal for modern manufacturers aiming to enhance efficiency and quality.

Compatible With Any Platform

Designed for versatility, our 3D-printed fixtures seamlessly integrate with a variety of popular tabletop platforms, including Blueco, Siegmund, Rhino, and more. This cross-platform compatibility makes them easy to implement without requiring modifications to your existing setup. Whether you’re working with steel, aluminum, or composite parts, our fixtures provide a stable, precise hold, ensuring accurate measurements. By fitting into multiple systems, they enhance flexibility, making them ideal for manufacturers seeking scalable, adaptable quality control solutions.

No Tools Needed

Say goodbye to cumbersome clamps and tools. Our magnetic fixtures hold parts securely in place without the need for additional hardware. This tool-free design allows for faster setup, reducing inspection time and increasing throughput. By eliminating the need for pins or manual fasteners, you can achieve consistent, repeatable accuracy with minimal operator effort. Perfect for busy manufacturing environments, these fixtures simplify quality control, making them a smart investment for boosting productivity and minimizing downtime.

Limited training needed

Our fixtures are designed with simplicity in mind, reducing the need for extensive operator training. The intuitive design allows users to perform accurate quality checks with minimal instruction, saving valuable time and resources. By streamlining the inspection process, your team can quickly verify that tubes and components meet precise specifications. This ease of use makes our fixtures perfect for high-paced manufacturing environments, allowing new employees to become proficient faster, improving overall productivity.

Created for Manufacturing

Increase your manufacturing efficiency with our go-no-go fixtures, specifically designed for rapid and accurate quality verification. These precision-engineered tools allow operators to quickly determine whether a part meets required tolerances, reducing the risk of defects. By streamlining inspection processes, you can minimize production delays and improve overall consistency. Our fixtures also help reduce material waste by catching errors early, making them a cost-effective solution for manufacturers focused on quality assurance and operational excellence.